Marsh

150 Person Marsh Standard Sewage Treatment Plant

150 Person Marsh Standard Sewage Treatment Plant

Couldn't load pickup availability

Description

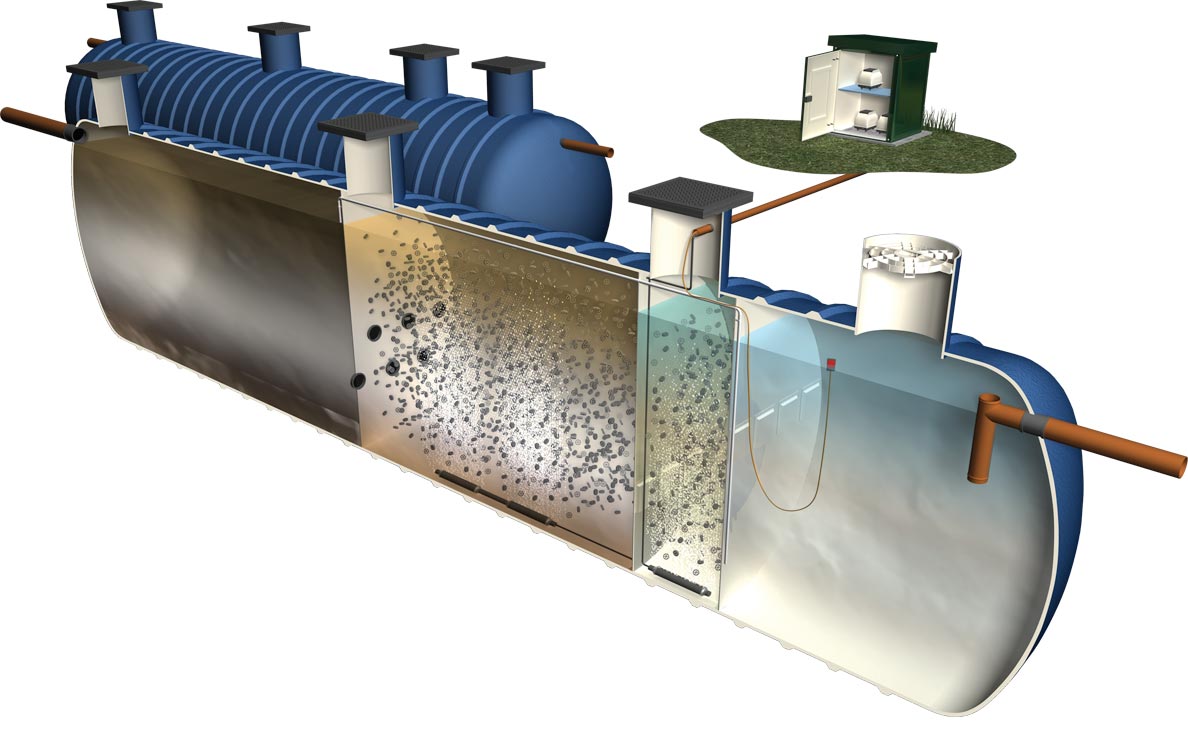

Marsh:Standard cost-effective sewage treatment systems provide biological treatment to off-mains wastewater on large residential, commercial, industrial and leisure sites ranging from 50-300+PE.

Proven reliability of the simple but effective Submerged Aeration Filtration (SAF-MBBR) system offers both operating and financial benefits when compared to more complex and expensive alternatives that require frequent servicing and maintenance to sustain performance.

Benefits

Plant sizing

Designed to BS12255, systems are available from 50-300+ PE in sizes ranging from Ø2.5-3m satisfying the demands of virtually all site conditions.

Class-leading effluent quality

Designed to British Water loadings (150litres per person, 60mg BOD litre and 8mg/litre Ammonia) ensures effluent discharge is well within national consent standards.

Cost-effective operation and maintenance

Systems have no internal moving parts and require minimal ongoing maintenance.

Heavy duty shell as standard

Structurally sound and built to last. Enables easy installation in all ground conditions.

High media surface area

High specification bio-media (310m3 per m2) and membrane diffusers provide even circulation to eliminate ‘dead spots’.

Low energy compressor(s)

Easily accessible low energy compressor for minimal running, maintenance and servicing costs. Integral alarm detects low pressure in air line.

Internal recirculation

Continues the treatment process to provide higher effluent quality whilst balancing flow over 24 hour period or periods of intermittent use.

Lockable manhole covers

600mm lockable manhole covers provide significant strength and durability, and helps to reduce possible odours.

Health and Safety considerations

The Marsh:Standard can be fitted with many safety features including turret guards, failure alarms for compressor components and high level alarms.

Optional extras

Optional extras include carbon covers for odour control, turret guards for additional safety, polylok filters to further reduce suspended solids, high level alarms and telemetry for monitoring, and risers/pumped outlets for deeper installations.

Manufactured in the UK

All units are manufactured in our twin manufacturing plants at Kettering and Bridgwater. The tanks are constructed using GRP (virgin unfilled resin – no ‘fillers’ such as chalk) providing consistent wall thickness ensuring superior structural strength and durability.

Specification

| Model up to | Width Ø +/- 50mm |

Length +/- 50mm |

Height +/- 50mm |

Inlet invert | Inlet Ø | Outlet invert | Outlet Ø | Turrets x 4 Ø | Desludge (days) |

|---|---|---|---|---|---|---|---|---|---|

| 50-55PE | 2500 | 4160 | 2950 | 600 | 160 | 800 | 160 | 600 | 90 |

| 60PE | 2500 | 4470 | 2950 | 600 | 160 | 800 | 160 | 600 | 90 |

| 70PE | 2500 | 5350 | 2950 | 600 | 160 | 800 | 160 | 600 | 90 |

| 85PE | 2500 | 6000 | 2950 | 600 | 160 | 800 | 160 | 600 | 90 |

| 100PE | 2500 | 6950 | 2950 | 600 | 160 | 800 | 160 | 600 | 90 |

| 125PE | 2500 | 8550 | 2950 | 600 | 160 | 800 | 160 | 600 | 90 |

| 150PE | 2500 | 10200 | 2950 | 600 | 160 | 800 | 160 | 600 | 90 |

| 200PE | 2500 | 13400 | 2950 | 600 | 160 | 800 | 160 | 600 | 90 |

| 250PE | 3000 | 9650 | 3450 | 600 | 160 | 800 | 160 | 600 | 60 |

| 300PE | 3000 | 9650 | 3450 | 600 | 160 | 800 | 160 | 600 | 45 |

Share